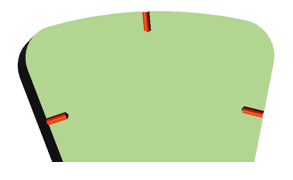

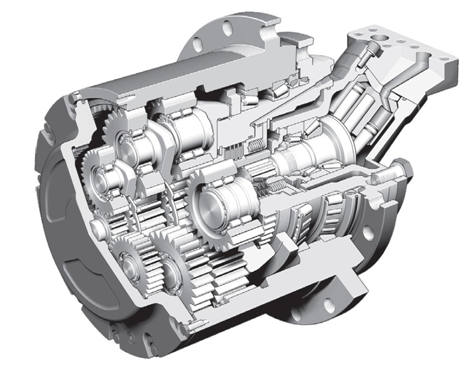

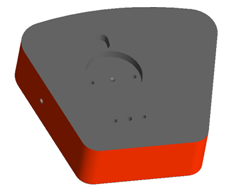

Thrustbearing bush is a part of Thrust Bearing. It is applied to fix transmissionshaft, and carries the axial force from transmission shaft. In addition, theforce is in axial direction which is helpful in thrusting.

It iscalled journal neck that supports bearings in thrustbearing, and the thrust bearing bush is the part matched with the journal.Thrust bearing bush touched to journal in thrust bearing directly, and thestructure of it would affect the bearing capability and lifetime of thrust bearing.The major problems we need to consider in designing the structure of thrustbearing bush would be: certain strength and performance of anti-friction shouldbe ensured, reliable performance of positioning in order to provide thelubrication conveniently, and it should be easy to assemble and adjust.

Thecommon materials machining for thrust bearing bush are classified as metalmaterials, powder metallurgy materials, and non-metallic materials. However, currentmaterials for thrust bearing could not meet all requirements mentioned above. Therefore,we could only select the materials that relatively satisfy the machining dependon the certain working condition for thrust bearings while designing the structures.The other way is to be improved by applying the thrust bearing bush structurewith various kinds of metals.

TheThrust bearing bush we introduced consists of carbon steel and Sn-based bearingalloy. Sn-based bearing alloy is suitable for high speed and heavy-load machiningdue to low friction coefficient, good performance of anti-glued, strongcapability of oil absorption, good performance of corrosion resistance andcapability of simple running-in.

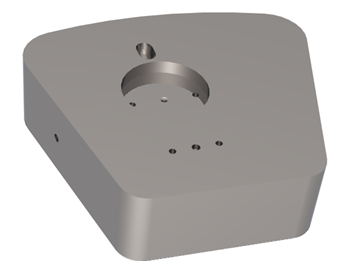

FaceMilling for Pedestal

Tool:FMA01-200-C60-SE12-12

Insert:YBG202/SEET12T3-DM

Cutting data:Vc=

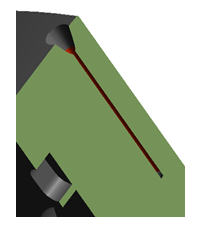

Sidemilling

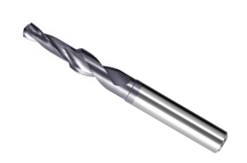

Tool:GM-2E-D14.0

Cutting data: Vc=

Hole Boring(Φ105)

Rough boring

Tool:RB04-CN63-87115

Insert:YBG202/CCMT120408-HM

Cutting data:Vc=

Finish boring

Tool:FB04-CN63-87134

Insert:YBG202/CCMT060204-HF

Cutting data:Vc=

Ramping(21*34)

Tool:GM-2E-D14.0

Cutting data:Vc=

Drilling (Φ10)

Tool:1534SU03-0960

Cutting data:Vc=

Hole Chamfering(Φ10)

Tool:1143SC90-2000

Cutting data:Vc=

Reaming (Φ10)

Tool:3102H7-1000

Cutting data:Vc=

Deep Hole-Making(D10*150)

Tool:1588SL

Cutting data:Vc=

Step Hole-making(M12)

Tool:1557SU03-M12

Cutting data:Vc=